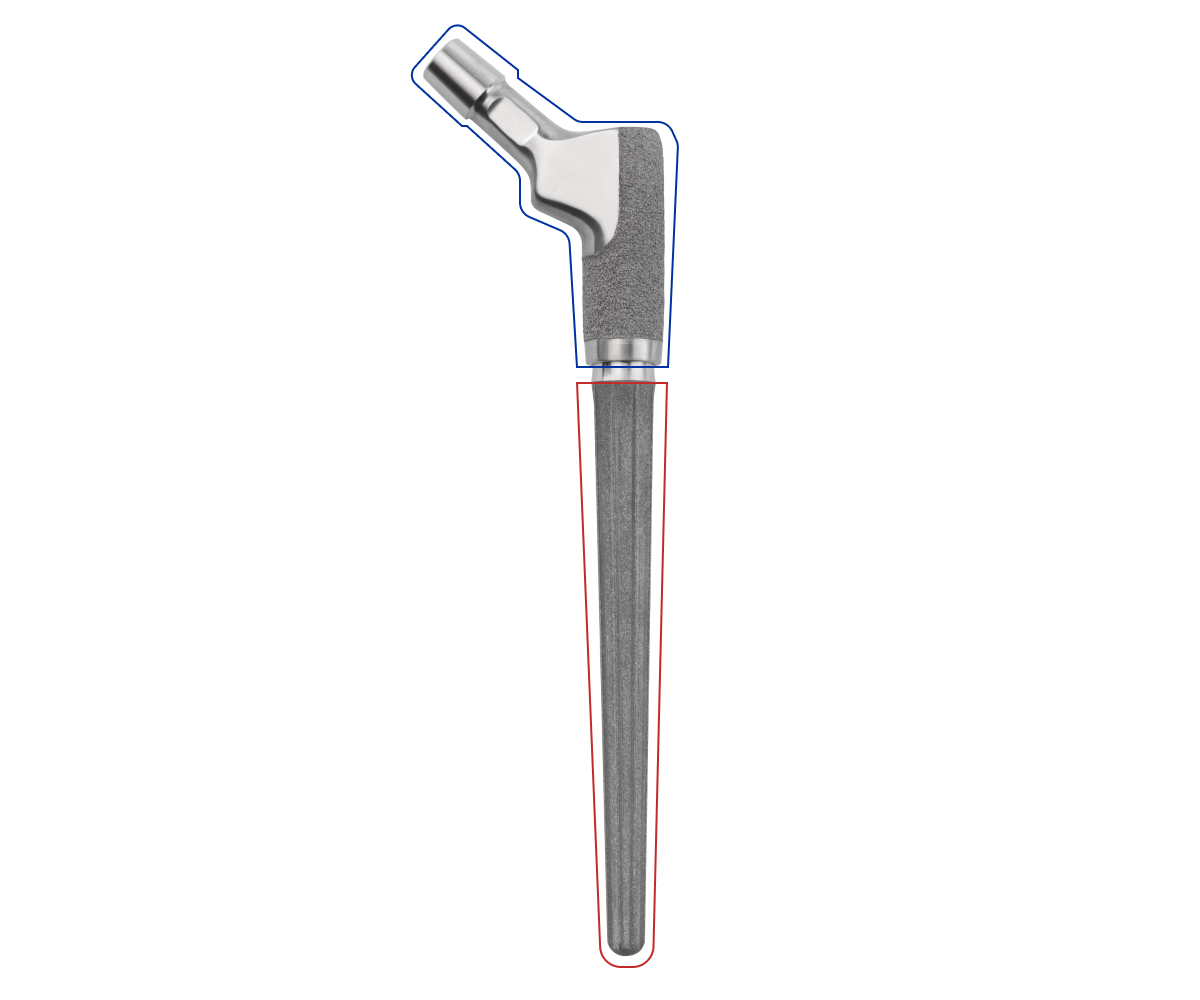

The unique combination of distal and proximal ends makes it easier to adjust the length of the prosthesis, better restore the biomechanical function of the joint, and freely adjust the anteversion angle of the femoral stem to ensure the flexibility of the prosthesis.

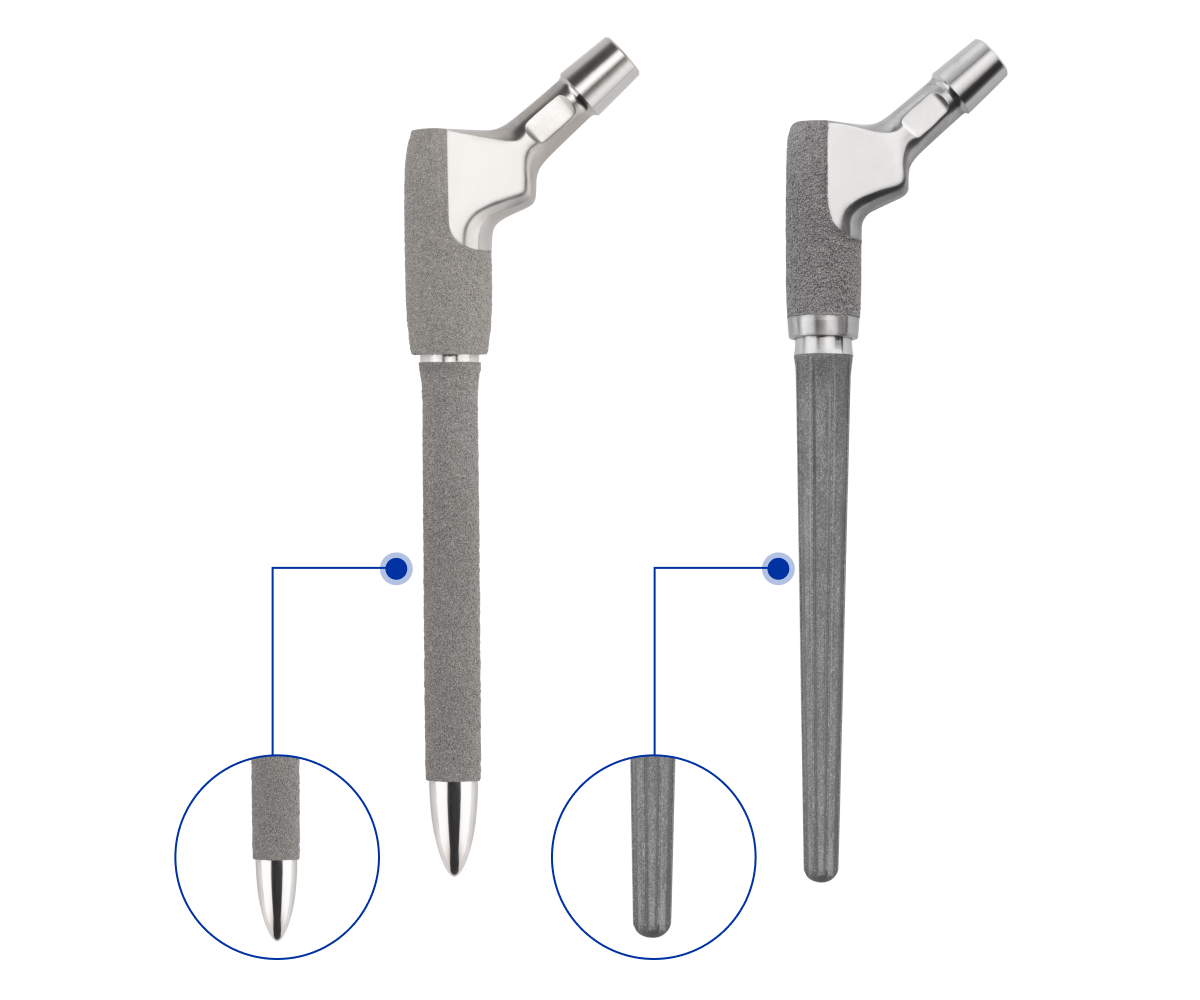

The ABM system uses a cylindrical and conical distal design to make the bone and prosthesis fit more closely and reduce the risk of bone splitting during femoral stem implantation.

The ABM system provides a choice of diameter and height for the proximal section, while using vacuum plasma spray coating technology to help better reconstruct the proximal femur, so that patients can better restore the normal function of the femur.

The design of ABM femoral stem instruments is based on the operation process and ergonomics, adhering to the principle of simplicity and fluency, minimizing the operation steps and improving the operation efficiency.